Smart Motor Control and Protection Solution

General

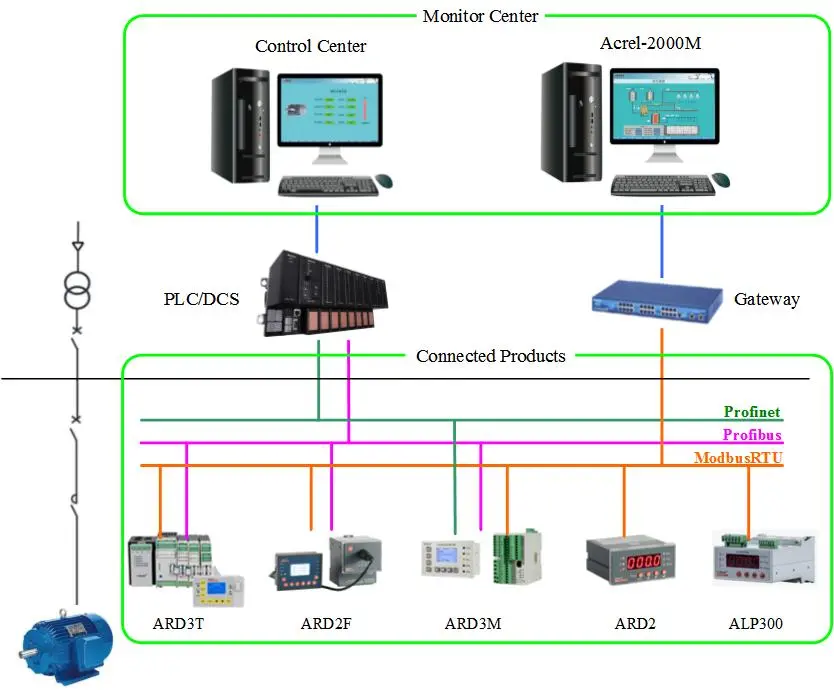

The motor is an important asset of the enterprise. It is necessary to monitor the running status and the efficiency of the motor, and protect the motor. Acrel ARD Series Smart Motor Protector is used for 660V low-voltage motor circuits with protection, measurement, control, communication, operation and maintenance function, can realize multiple starting schemes to ensure the safe operation of the motor. It can be connected to the intelligent MCC or DCS production system. It is widely used in Chemical Industry、Power Plant、Pump Station、Mining Industry、Metallurgical Industry and so on.

Application Scenario

• Chemical Industry

• Power Plant

• Pump Station

• Mining Industry

• Metallurgical Industry

Certification

• CE

Structure

Communication

• Modbsu-RTU

• Modbus-TCP

• Profibus-DP

• Profinet

Main Functions

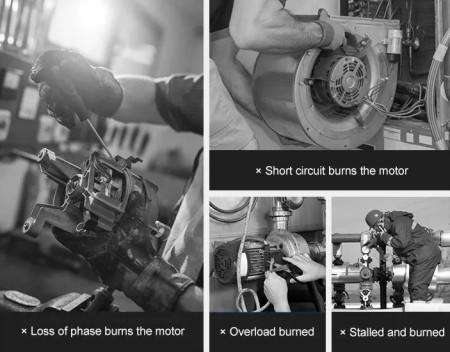

• Protection Function

| Start timeout | External Fault | UnderPower |

| Overload | Insulation Fault | tE time |

| UnderLoad | OverVoltage | Loss of pressure (anti-shake) |

| Short circuit | Undervoltage | |

| Blocking | Phase Failure | 4-20mA input protection |

| Stall | Phase Sequence | Ground |

| Unbalance | OverPower | Leakage |

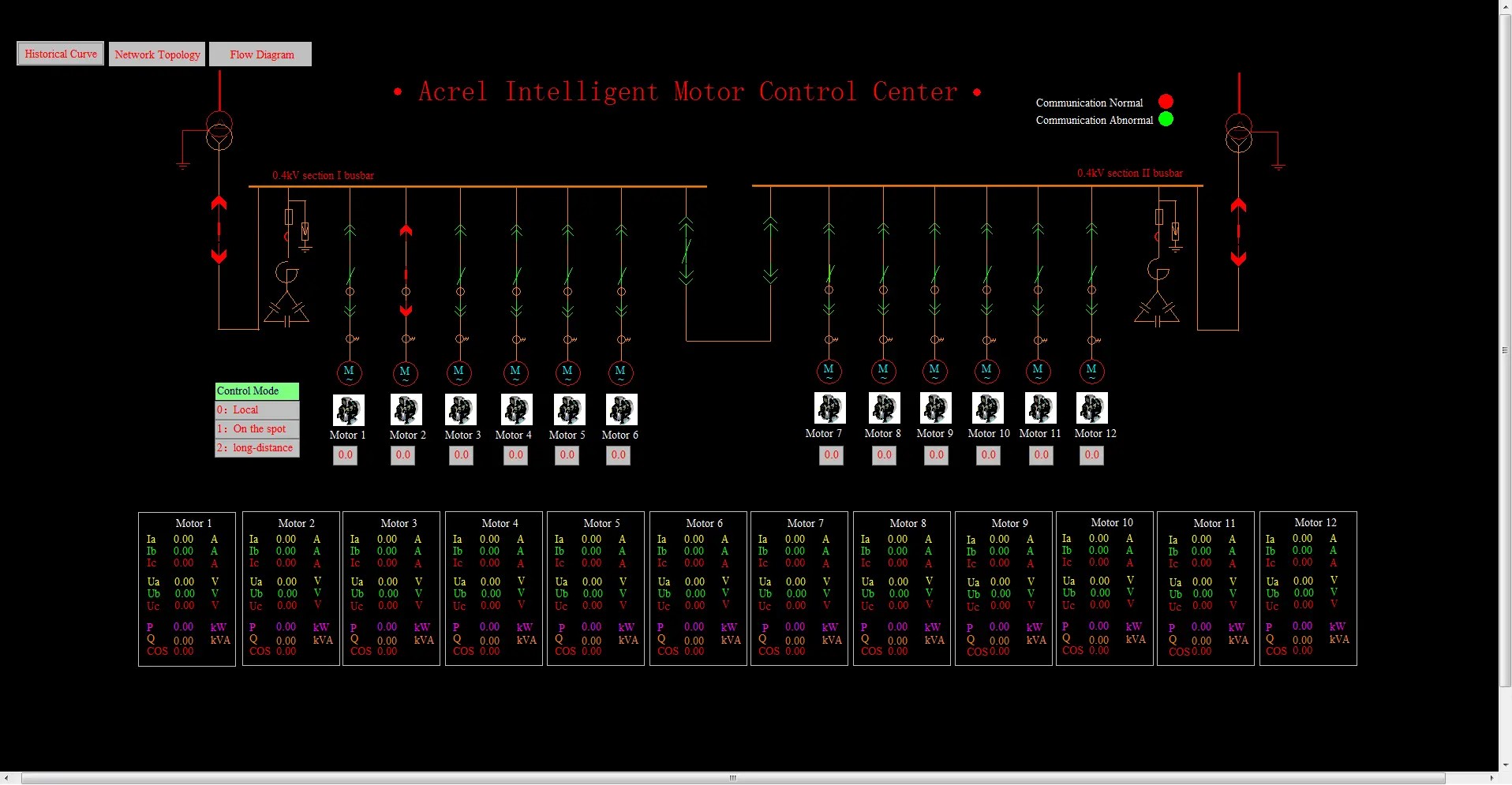

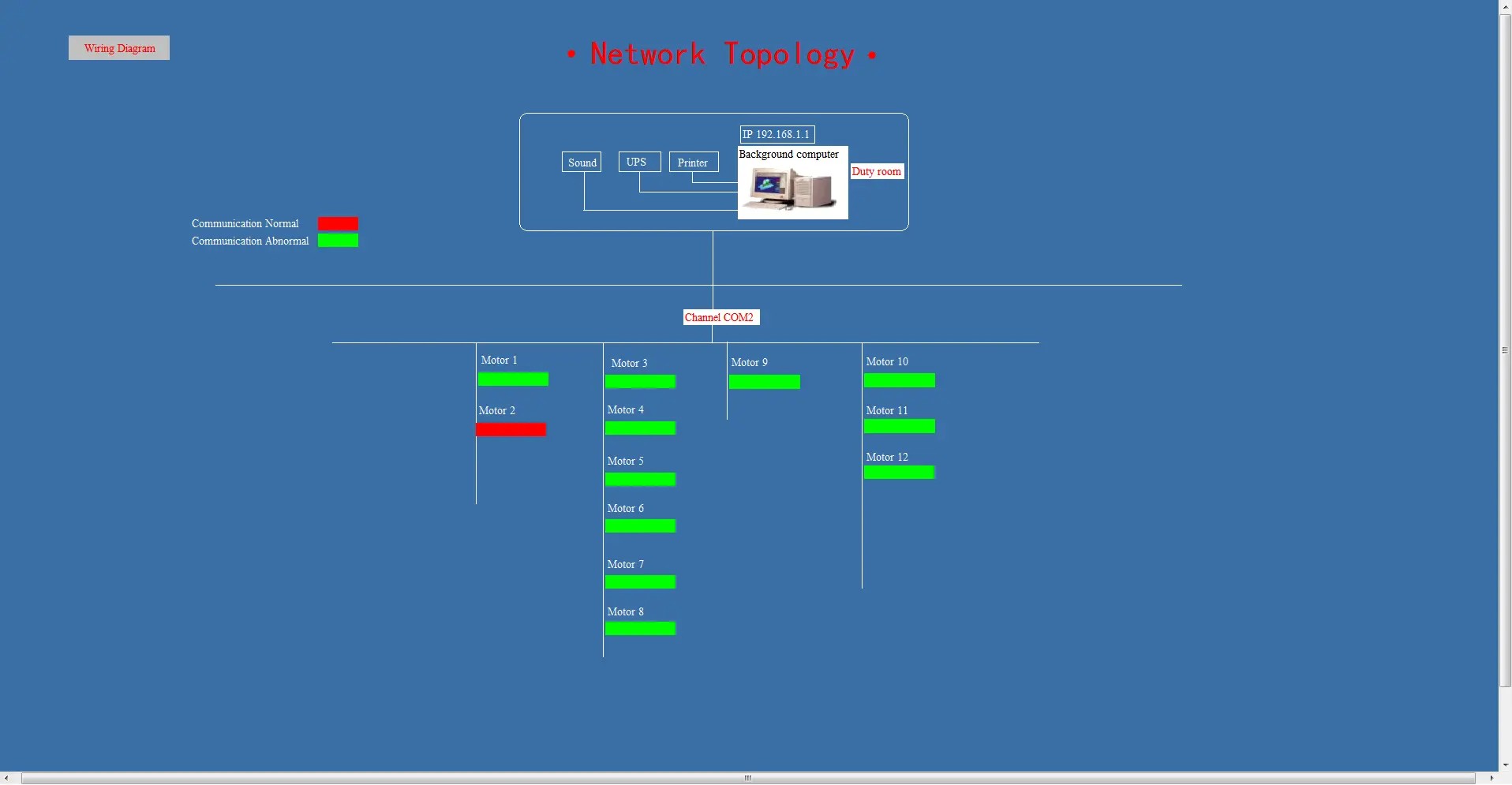

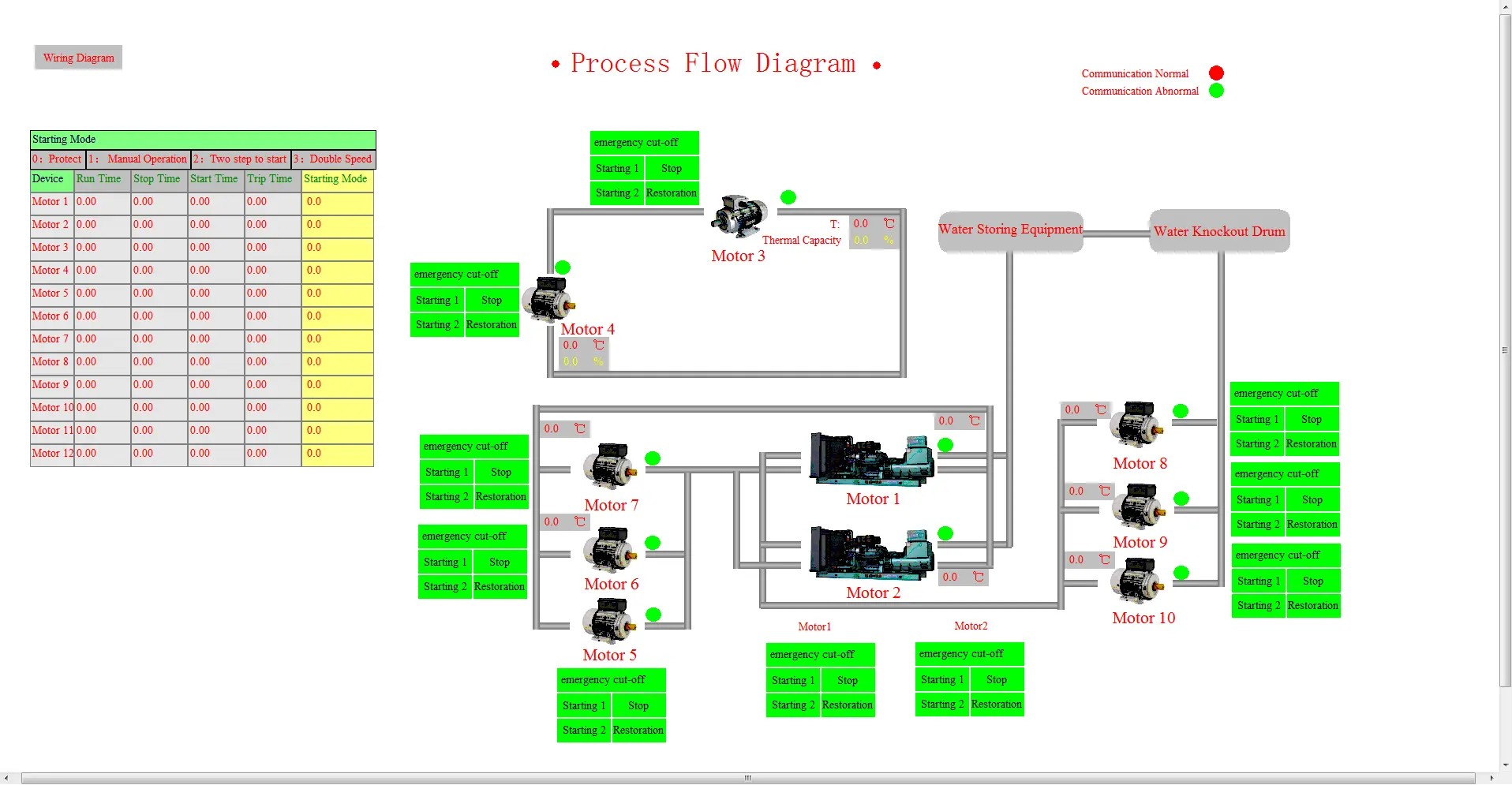

Human Machine Interface

On-site Pictures

Product Selection

| Function | ARD2/ARD2L | ALP300 | ARD2F | ARD3 | ARD3T | ARD3M | |

| Application | Low voltage 0.4kv-1.14kv motor protection | ||||||

| Protective function | Start timeout | √ | |||||

| Overload | √ | ||||||

| Underload | √ | ||||||

| Short circuit | √ | ||||||

| Blocking | √ | ||||||

| Stall | √ | ||||||

| Unbalance | √ | ||||||

| External Fault | ■ | ■ | ■ | √ | √ | √ | |

| Insulation Fault | √ | ||||||

| OverVoltage | √ | ■ | ■ | ■ | √ | ||

| Undervoltage | √ | ■ | ■ | ■ | √ | ||

| Phase Failure | √ | √ | √ | √ | √ | √ | |

| Phase Sequence | ■ | ■ | ■ | √ | |||

| OverPower | ■ | ■ | ■ | √ | |||

| UnderPower | ■ | ■ | ■ | √ | |||

| tE time | ■ | ■ | ■ | √ | |||

| Loss of pressure (anti-shake) | ■ | ■ | ■ | ■ | |||

| 4-20mA input protection | ■ | ||||||

| Ground | √ | ||||||

| Leakage | ■ | ||||||

| Communication function | ModbusRTU | ■ | ■ | ■ | ■ | √ | |

| Double ModbusRTU | ■ | ■ | ■ | √ | |||

| Profibus DP | ■ | ■ | ■ | ■ | |||

| Doubel Profibus DP | ■ | ||||||

| Profinet | ■ | ||||||

| Modbus TCP | ■ | ||||||

| Switch input | 2 | 2 | 9 | 9 | 8 | 10 | |

| Relay output | 4 | 4 | 5 | 5 | 7 | 6 | |

| Start control | ■ | √ | √ | √ | |||

| 4-20mA analog output | ■ | ||||||

| Record | ■ | ■ | ■ | ■ | √ | ||

| Operational information record | √ | √ | |||||

| Logic function | √ | √ | |||||

| Parameter measurement | Three-phase current | √ | |||||

| Leakage current | ■ | ||||||

| Three-phase voltage | ■ | ■ | ■ | √ | |||

| Power, power factor | ■ | ■ | ■ | √ | |||

| Frequency | √ | √ | √ | √ | |||

| Electric energy | ■ | ■ | ■ | √ | |||

| PTC/NTC | ■ | ■ | √ | √ | |||

| 4-20mA input | ■ | ||||||

| Temperature measurement module | ■ | ||||||